Learn more about Hop-Up here

What is a hop up?

Your hop up is one of the most important parts of your rifle, it is what, in conjunction with your barrel, makes your rifle shoot far and straight.

The hop up consists of a hop up chamber, hop up rubber and hop up nub that assemble around the barrel.

The way hop up works is always the same, but there may be differences in how the individual parts are assembled.

What does a hop up do?

Your hop up rubber presses on the ball as it passes and causes it to roll backwards in the air, this keeps it floating for a much longer distance.

A typical normal hop-up in an AEG consists of a rubber with a round inner knob that is pressed down by a nub, often the nub is made of a hollow piece of rubber.

In the hop up chamber there is an arm with space for the nub, which is adjusted down via a wheel and therefore presses on the rubber.

Where is my hop up?

Your hop up is always in your weapon so it is easily accessible, but still protected as much as possible.

In AEG rifles, it is located at the top of the magazine well and is often accessible through the dust cover on the side, this is usually opened by pulling the charging handle on the back of the rifle.

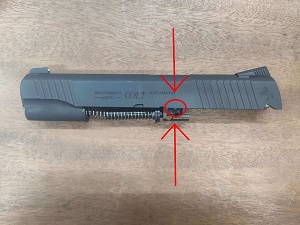

In gas pistols with blowback, the hop up can often also be found at the front of the magazine well, where you can see it if you pull the slide back.

On these pistols, the slide often has to be removed before the hop up can be adjusted.

How do I adjust my hop up?

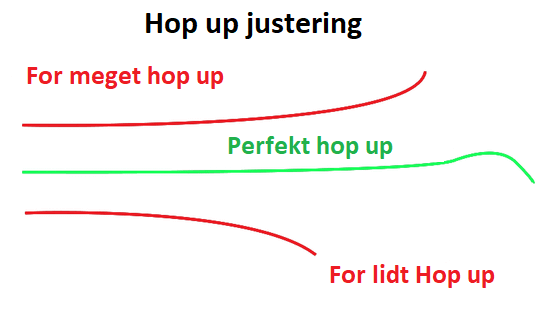

Your hop up is adjusted by turning the chamber wheel, direction is often shown on the chamber, a little at a time.

With each adjustment you will see that your weapon shoots a little further than before, the optimal adjustment is a long straight trajectory with a small jump at the end.

If you adjust your hop up too much, the bullet will come out and rise into the air quite quickly before it reaches its optimal shot length.

If the hop up is adjusted too much, the bullet will get stuck in the chamber. It is very important to stop shooting to avoid damaging your rifle.

What do I do if my hop up doesn't work?

If your hop up is behaving strangely or not working at all, it could be due to several different things:

- If your hop up seems very unstable after adjustment, there may be damage to your hop up rubber, this should be replaced by someone with experience to ensure that it is assembled properly.

- If you cannot get any hop up effect at all after adjustment, your hop up rubber may be greasy. This requires a thorough cleaning of the rubber inside and requires removing the chamber and barrel from the weapon.

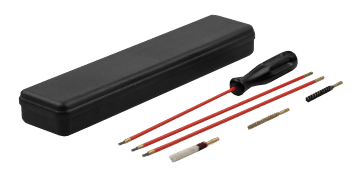

- If after adjustment you can get the optimal trajectory but your shots seem very imprecise, it is often because your barrel needs a thorough cleaning, we recommend a proper cleaning kit for this.

Should I upgrade my hop up chamber?

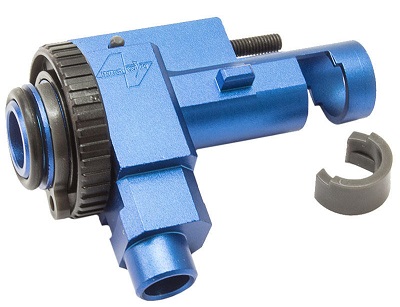

When looking at hop up chambers, they are typically divided into two types, the old ones with gears and the new ones which are rotating.

The primary reason to change the hop up chamber from gear to rotary is to change the axis you adjust on, it is often seen that the older model becomes loose over time and therefore does not hold the adjustment.

If the rifle already comes with a rotating chamber, we recommend keeping this as they often match the rifle best.

If you still want to upgrade, we recommend Prowin or MAXX hop up chambers as the best on the market.

Which rubber should I choose?

When you want to replace your hop up rubber, it can seem confusing at first as there are many types to choose from.

The most important thing is to choose a rubber with the optimal degree, this refers to how hard the rubber is, which has an impact on how well it can grip the ball depending on the output speed/output energy.

We recommend that you roughly follow this (Measured with a 0.20g):

90-110 m/s = 50-60 degrees

110-140 m/s = 60-70 degrees

140+ m/s = 70+ degrees.

In addition to this rule of thumb, there are of course some rubbers we can always recommend:

Krytac rubber combined with a maple leaf nub is our preferred solution when tuning rifles in the workshop, the rubber is at about 60 degrees and is perfectly suitable for most standard AEGs.

Green G&G rubber is a well-known and well-tested rubber that is always good to have on hand in case of problems on game day, their newer blue rubber is also recommended.

Maple leaf rubber are known for their internal flat knobs and specified degrees, combined with their own nub it gives a really good pressure surface especially for rifles that shoot over 140 m/s.

Are there advanced types of hop ups?

If you are the type who always chases the very latest, there are of course also hop up solutions that require extra work, but these solutions also provide a better pressure surface and therefore more consistent results.

Flat hop:

When making flat hops, take your favorite rubber, we recommend the green G&G, and turn it inside out, then carefully cut off the knot and guide groove.

Finally, the rubber is polished, often with a fine file, so that it looks completely smooth on the inside. When it is turned normally and put on the barrel, it is turned 90 degrees so that an untouched inside of the rubber is used.

Combined with, for example, a Maple Leaf nub, this gives a larger pressure surface and therefore really nice results.

R-hop:

If you want to take it a step further, R-hop is the next solution. Here you make a patch in very specific rubber tubing that precisely fills the hop-up window in your inner barrel. This should be done by an experienced mechanic.

Then you make a flathop rubber and put it on the inner barrel together with, for example, a Maple Leaf nub. This solution provides the second largest pressure surface and gives fantastic results with especially heavy bullets in, for example, DMR and bolt action rifles.

ER hop:

ER-hop is a further development of R-hop, here you expand the window in your inner race, this should be done by a professional on a machine for the best results.

Then you make an R-hop patch for the new window and finish with a flathop rubber. This gives the largest possible pressure surface but may require a custom-made nub in the hop up chamber.

This provides the best possible results in DMR and Bolt action rifles.